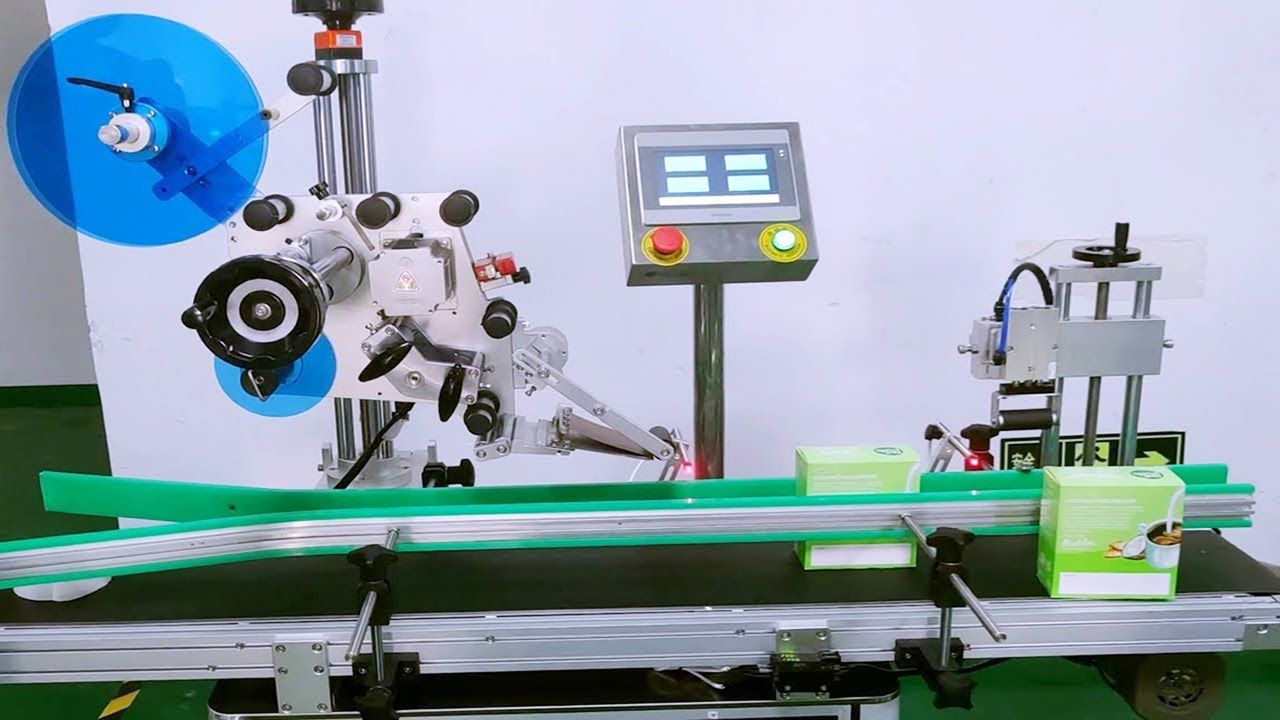

Labeling is one of the most important stages in manufacturing and it is a very sensitive stage in the fast-moving world. Labeling supplies product information that is valuable for branding, instructions on how to use the product, and legal requirements to produce and use the product. Corner labeling machines have emerged as a revolution in industries that involve labeling processes that are accurate and fast. These machines are intended to label products at the corners or edges of the products to increase the accuracy, appearance, and general outlook of the products. The corner wrap labeling solution offers a precise and efficient method of labeling, ensuring that every corner is labeled correctly for enhanced product presentation.

Accuracy and Uniformity

This is one of the biggest strengths of corner labeling machines – you are guaranteed accuracy and uniformity. The conventional methods of labeling by hand can be very inaccurate and may result in misaligned or uneven labels. Corner labeling machines, on the other hand, are automated labeling systems that come with sophisticated sensors, and are mechanically designed to accurately identify the position of the label on the corners and then place the label on it in a standard position.

Enhanced Appearance of Products

In the highly competitive market, the appearance of the product is very important in influencing the consumers. Corner labeling machines are used to give the products a more professional and neat appearance by the manufacturers. Through proper labeling of the corners, the machine is able to avoid covering up the design of the product hence improving the aesthetic value. This is especially applicable to luxurious goods or those whose promoters’ goal is to give some sort of classy or luxurious imagery.

Improved award and incentive programs.

Another advantage of corner labeling machines is efficiency. These automated systems are intended to enhance the labeling process, and the time taken to apply labels is considerably less than when using manual methods. Corner labeling machines are designed to place labels on several products within a shorter time than it would take an employee to individually place and apply each label.

Enhanced Durability of Labels

Apart from enhancing the aspect of product presentation, corner labeling machines also guarantee that labels stick well to the product. The application systems built into these machines appropriately apply the labels using the correct pressure and adhesive so that they remain stuck on the machines for longer durations. This is especially so for products that are likely to be exposed to some form of abuse during transportation, warehousing, or shelf placement.

Flexibility for Different Kinds of Products

The other benefit of corner labeling machines is that they are flexible. These are multifunctional packaging machinery capable of handling the packaging of various products, be it jewelry, perfumes, electrical appliances or gadgets, cosmetic products, detergents, shoes, smaller items, as well as large items such as boxes, cartons, or whatever packing material that is required. Corner labeling machines are helpful especially for firms with various products since they can switch it to suit numerous sizes and shapes.

Conclusion

Labeling machines, especially the corner ones should be adopted because they have numerous advantages that enhance product presentation and accuracy. These machines are accurate, can improve the looks of products, and have improved the speed of labeling making them an essential tool in the current world.